Technical Consultation

Get expert technical advice on product design, architecture, hardware-software integration, and prototyping. Ideal for startups and engineering teams.

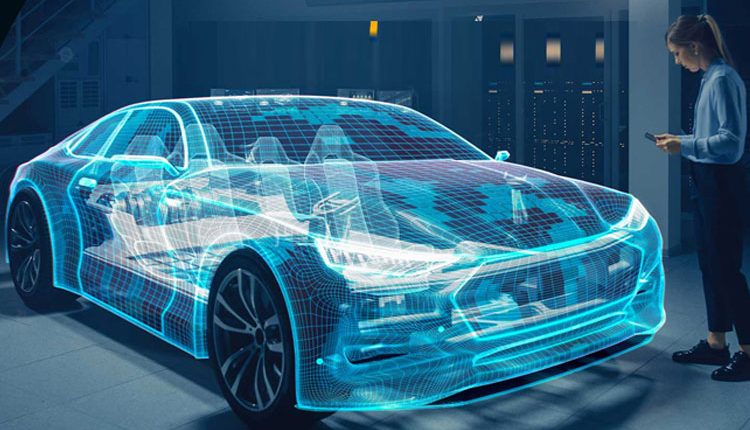

At Kaamaa Technologies, we specialize in delivering state-of-the-art engineering solutions by leveraging cutting-edge technologies across multiple industries. Our expertise spans automotive, electric vehicles (EVs), aerospace, consumer electronics, and industrial automation, ensuring innovation,efficiency, and sustainability in every project.

Get expert technical advice on product design, architecture, hardware-software integration, and prototyping. Ideal for startups and engineering teams.

Strategy sessions for product-market fit, business models, GTM plans, pricing, and investor preparation. Helpful for founders and product managers.

Pick a convenient slot for detailed discussions. We offer virtual calls, on-site visits (Chennai), and follow-up reports after the meeting.

By combining cutting-edge tools, expert knowledge, and a problem-solving approach, we help businesses optimize processes, reduce development time, and gain a competitive edge in their respective markets. At Kaamaa Technologies, innovation meets execution to create lasting impact.

Kaamaa Technologies is a leading R&D service provider specializing in electric vehicles (EVs), offering cutting-edge solutions to enhance performance, efficiency, and sustainability. We support Tier 2 and Tier 3 companies with advanced design, prototyping, testing, and optimizationservices, ensuring cost-effective and high-performance EV innovations.

At Kaamaa Technologies, our Research & Development (R&D) services drive innovation, efficiency, and sustainability across industries. We specialize in concept design, prototyping, CAD modeling, and reverse engineering, delivering tailored solutions that address complex engineering challenges.

Our expertise spans automotive, aerospace, consumer electronics, industrial machinery, and agriculture, where we employ advanced technologies to enhance product performance, durability, and cost-effectiveness. Through rigorous testing, analysis, and continuous improvement, we ensure precision-engineered solutions that meet global industry standards.

Kaamaa Technologies specializes in concept design services tailored for EV (Electric Vehicle) development and advanced automotive R&D. Our expertise includes

Precision Cutting & Bending:

Welding & Assembly:

Once we have fully detailed thedesign, rendered the proposed

fit and finish, and simulated itsperformance, we bring your

design to life through a prototype.We make use of a wide varietyof prototyping methods to producethe first physical version ofyour product which includes

Lightweight & High-Strength Materials